PolySorb case study before and after install effectiveness.

By Soundpost Acoustics

PolySorb Case Study Example: In 2022 Abiding Hope Church in Littleton, Colorado embarked on a project to refurbish the Family Life Center, a multipurpose room in their church building. Jim Sponnick at Abiding Hope Church commented “Our first steps in refurbishing the Family Life Center were removal of the carpeting and polishing the concrete. The floor looked great, but the resulting acoustics in the room were extremely poor, to the great detriment of the many events and musician rehearsals that occur in this space. “

Soundpost Acoustics was subsequently called in to evaluate the troublesome acoustics in the room and make recommendations for improvements. During our evaluation visit we found an extremely live room that made social gatherings and music rehearsals extremely difficult and made speech unintelligible, especially when amplified. The room clearly needed new sound-absorbing finishes to treat the acoustics, but aesthetics and budget were also major factors to be considered, and there were many questions about how to proceed: What would the optimal treatment materials be? How much treatment would be needed? Where should the new treatment materials be located?

The room had a concrete floor, tables and chairs, gypsum board walls and a peaked ceiling with a textured gypsum board finish. The ceiling seemed to be a good place to start, since it offered the most available surface area, but questions remained about how much surface area was needed for treatment and what material would be best suited for the situation.

“After reaching out to Soundpost Acoustics and discussions about how we use this room, they made detailed measurements. They then performed analyses and assessed options, subsequently providing an outstanding set of recommendations for taming our out-of-control acoustics.”

-Jim Sponnick, Abiding Hope Church

Photo of Family Life Center during the evaluation visit. The textured gypsum board ceiling was highly sound reflective.

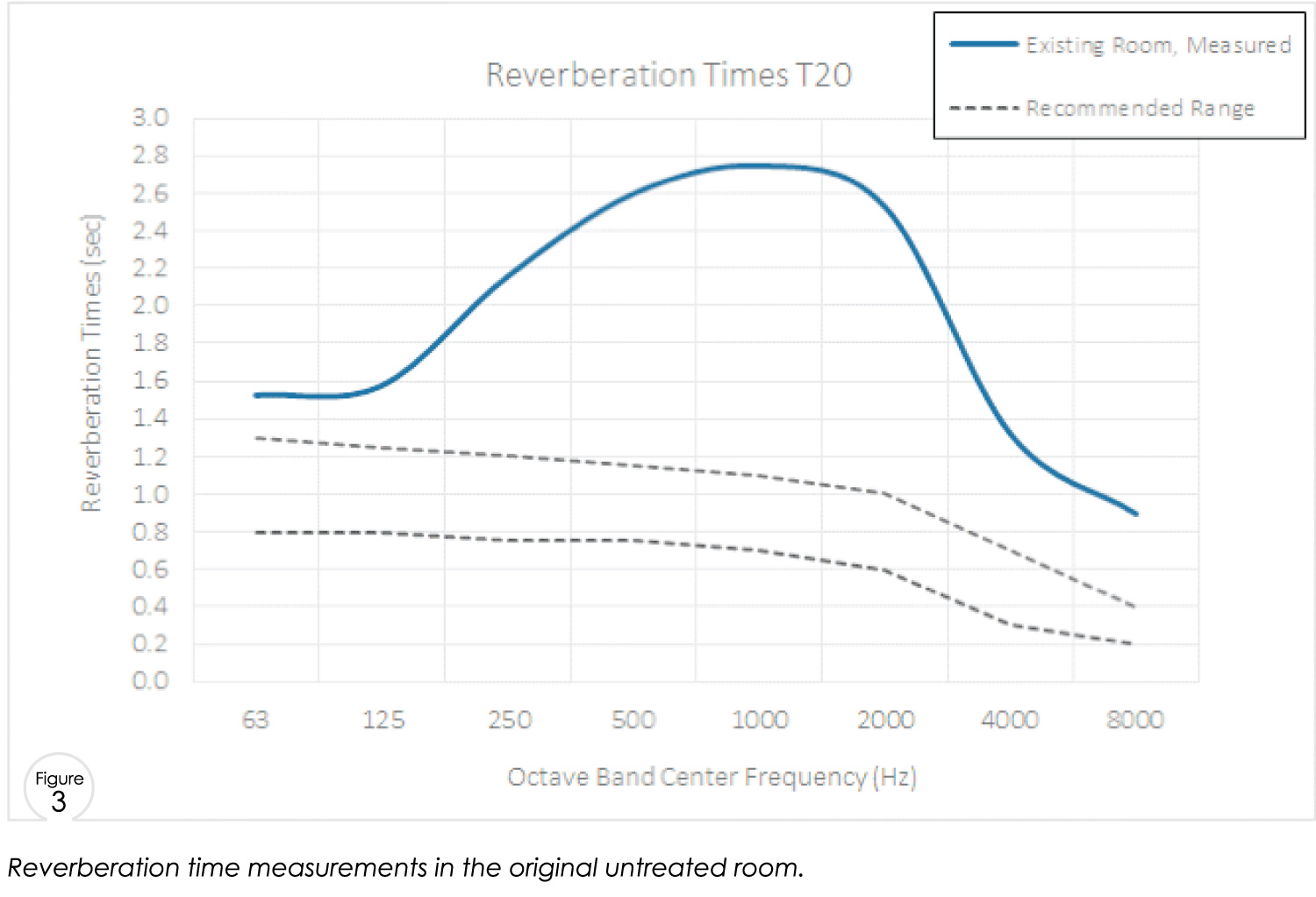

To answer these questions, we started by making acoustics measurements in the room. During the measurement session we set up a loudspeaker to play a test signal and a pair of microphones to capture the acoustical response of the room. To capture an overall room average, the loudspeaker was aimed in different directions and the microphones were moved around the room. We averaged the individual measurements together in order to arrive at an overall reverberation time curve. This process resulted in the dark blue curve “Existing Room, Measured” below, showing the reverberation times (T20) versus frequency. Note that this curve reaches a maximum value of around 2.7 seconds between 500Hz– 2,000Hz, which corresponds to the frequency range of the human voice. This result certainly confirmed the Client’s complaints about the room’s acoustics, and greatly exceeded our recommended range shown by the dashed lines in Figure 3.

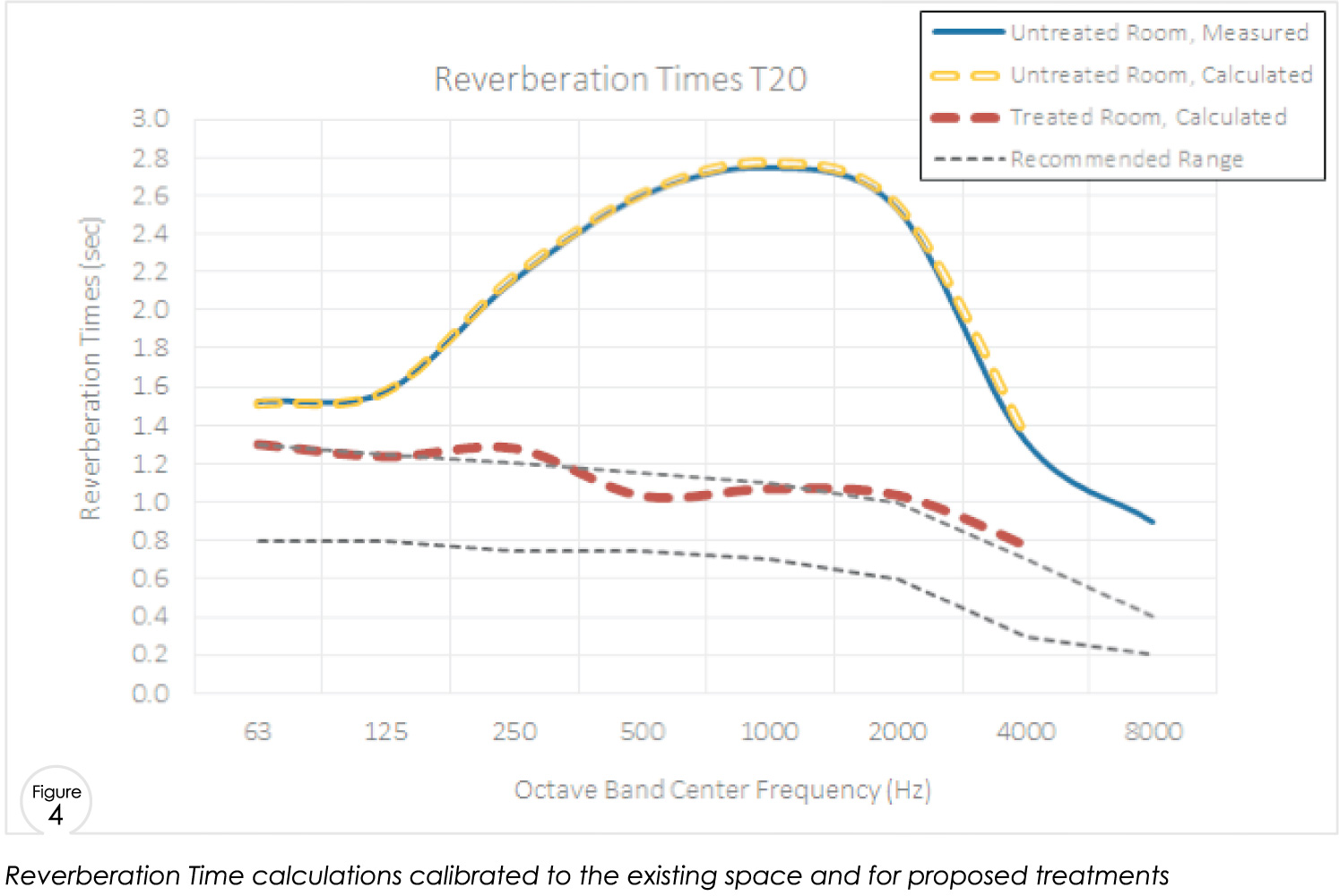

Following the measurement session, we calculated reverberation times using the Sabine equation. For this calculation, absorption coefficients are needed for each of the materials in the room. Absorption coefficients describe how much sound the material absorbs. A highly sound-reflective material like concrete, for example, has a very low absorption coefficient, while an absorbent material such as fiberglass has a high absorption coefficient. In this case, we started from standard values for the various materials in the room, and then adjusted them slightly until a close match between the calculation and the measurement was achieved, as seen in Figure 4. More on these absorption coefficients later …

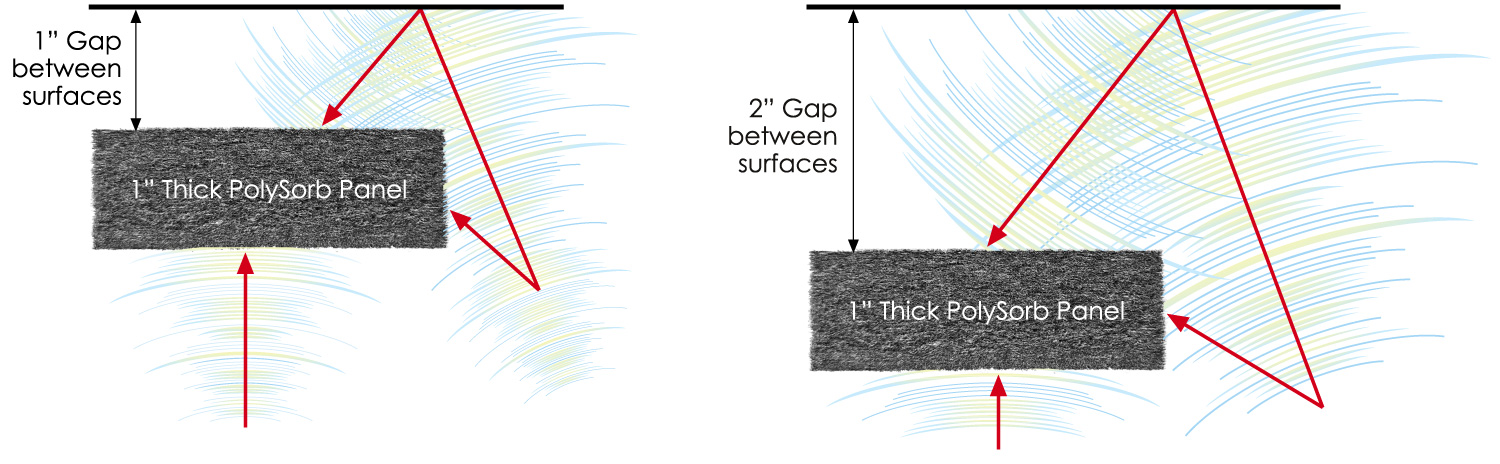

The calculation also allowed us to explore various options for acoustical treatments in the space. We settled on 1” thick PolySorb polyester panels covering a minimum of 2000sf of the ceiling, further recommending that the panels be mounted with a 1” airspace to enhance absorption at lower frequencies. This amount of new treatment, in addition to a smaller area of sound-absorbing material at the front wall, yielded an estimate for the treated room which would reduce reverberation times to the upper end of our recommended range (dark red dashed line) in Figure 4.

The calculation also allowed us to explore various options for acoustical treatments in the space. We settled on 1” thick PolySorb polyester panels covering a minimum of 2000sf of the ceiling, further recommending that the panels be mounted with a 1” airspace to enhance absorption at lower frequencies. This amount of new treatment, in addition to a smaller area of sound-absorbing material at the front wall, yielded an estimate for the treated room which would reduce reverberation times to the upper end of our recommended range (dark red dashed line) in Figure 4

With the basic treatment recommendations now set, Contour Audio & Acoustics was brought in to design the PolySorb panel layout and perform the installation. Contour took a panelized approach to the design, leaving consistent gaps between panels, and staggering adjacent rows for visual interest. The PolySorb material had to be cut around various elements already in the ceiling, including light fixtures and HVAC openings. Several detail images of the final installation are below:

“The PETClip impalers were great to work with. We used them in conjunction with a furring strip to stand the boards off of the popcorn ceiling. It worked seamlessly and allowed all of the mounting hardware for the panels to be hidden which was an aesthetic the client appreciated” – Ryan B. Contour Audio & Acoustics

“Ryan and the team at Contour did an excellent job in

designing and installing our acoustic treatments.“

– Jim Sponnick – Abiding Hope Church

Subjectively, the room was immediately transformed with the installation of the new ceiling treatment and the client was pleased with the result. Jim Sponnick said “the recommended acoustic mitigations from Soundpost Acoustics improved the aesthetics in the Family Life Center and most importantly they dramatically improved the room acoustics.”

It was clear that reverberation times had been greatly reduced, but by how much?

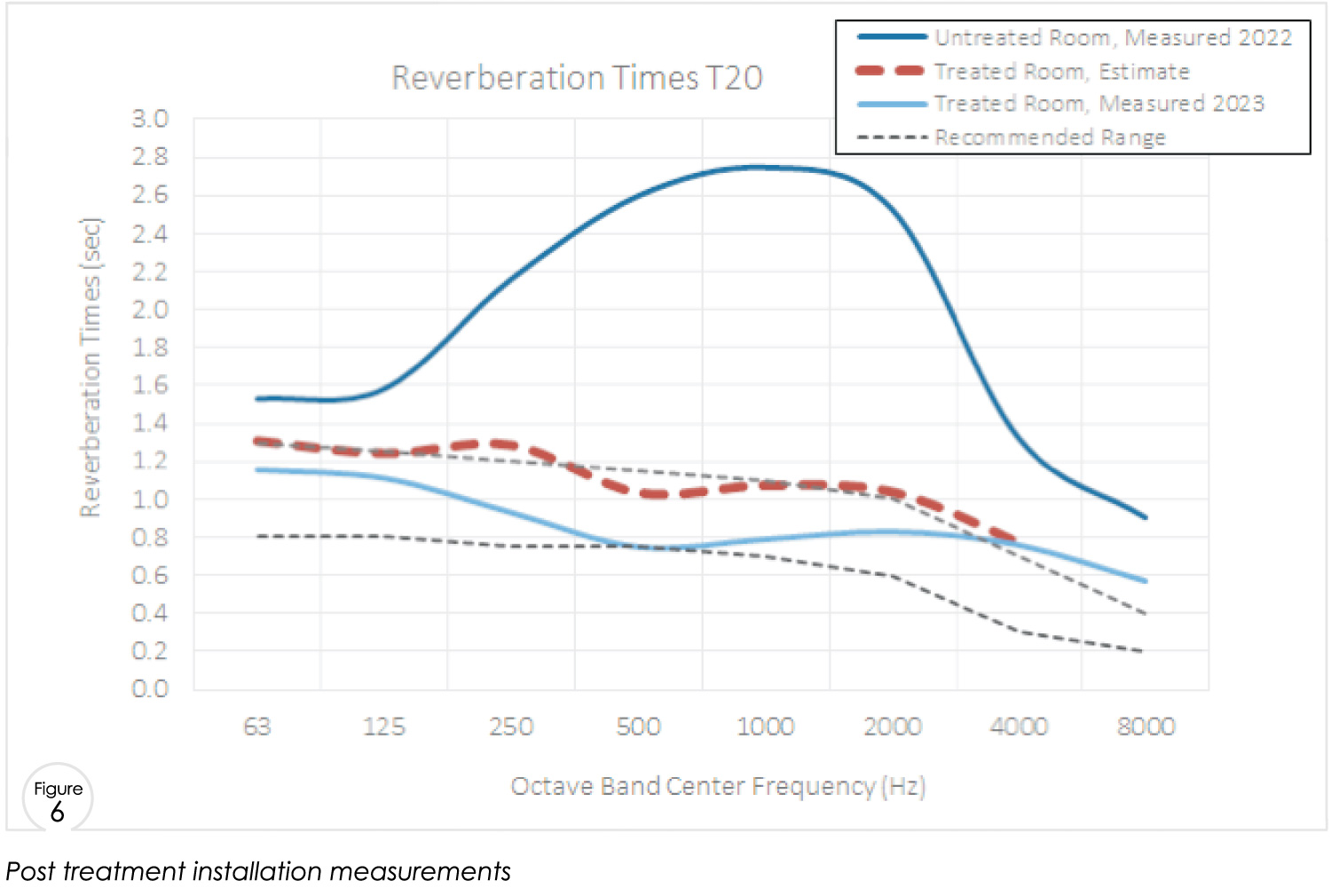

In late 2023, we returned to the room to repeat our initial reverberation time measurements. During this measurement session, we found that reverberation times had been reduced to around 0.8 seconds at mid-frequencies, below our original estimates and into our recommended range. While this surely represented a successful installation, how could we account for the remaining difference between our original calculation and the measured result shown in Figure 6 (i.e., dashed red line compared to solid light blue)?

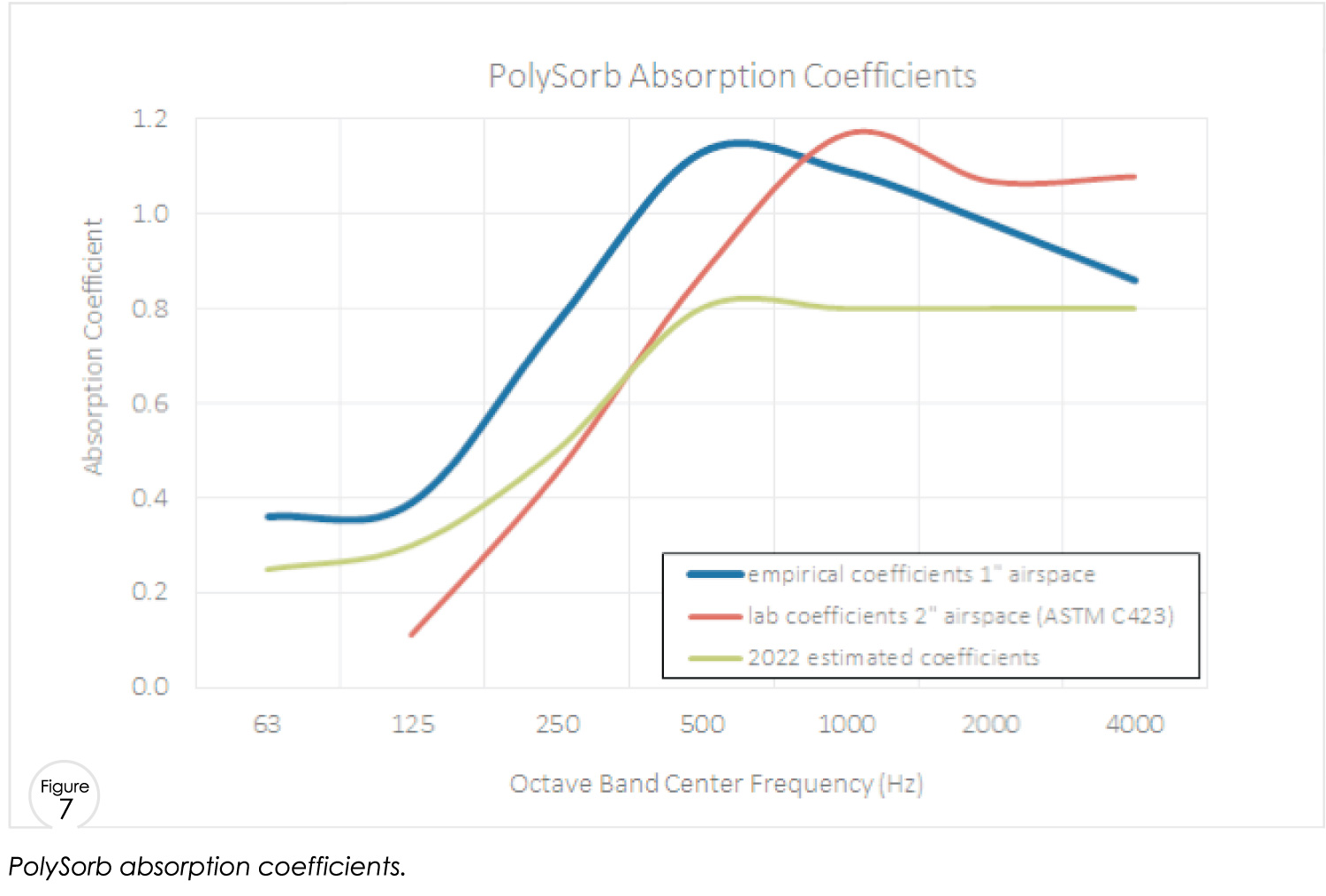

With the new set of measured reverberation time data in hand, we re-visited the Sabine calculation for the original report. While there were a few minor differences between the two measurement sessions, including a small area of treatment on the front wall, and some minor setup differences in the room, we concluded that the primary factor that reduced the reverberation times must be the change of absorption along the ceiling. We corrected the actual PolySorb surface area that was installed (2124sf) and adjusted the absorption coefficients in the calculation to match the actual measured reverberation time data. As shown in Figure 7, these “empirical” absorption coefficients turned out to be a bit higher than our original estimated coefficients. In the meantime, we had also received laboratory absorption data for PolySorb from the manufacturer, allowing the 3-way comparison of absorption coefficients shown in Figure 7.

While the three absorption coefficient curves in Figure 7 show similar trends, they also reflect some interesting differences. The empirical coefficients exceed both our original estimates and the lab coefficients between 125-500Hz by a significant margin. It seems that our original estimated coefficients were conservatively low.

The lab coefficients are for PolySorb with a 2” airspace, which would be expected to increase low frequency absorption compared to a 1” airspace, but the opposite trend is seen here. One explanation for this result is that the gaps provided between panels in the installation (see Figure 5) increased the effective surface area of the PolySorb by allowing more sound to find its way to the edges and the rear side of the material. In the laboratory, the PolySorb test sample was as a continuous sheet without gaps in between sections, exposing only the perimeter edge to the test chamber.

Another important factor is that the PolySorb was installed on a gypsum board ceiling, while in the laboratory setting it was tested against a concrete slab. This installation difference would account for the differences seen at 125Hz between the dark blue and the red curves in Figure 7.

This case study highlights a very successful project. The acoustical performance of the PolySorb exceeded our expectations and a tremendous reduction in reverberation times was achieved. Contour provided a beautiful design and a craftsman-quality installation. Most importantly, our Client was pleased with the result!

“We are extremely happy with the results and it was a

great pleasure working with Soundpost on this project!”

– Jim Sponnick, Abiding Hope Church