PolySorb Polyester Acoustic Panels Call 206-571-5710

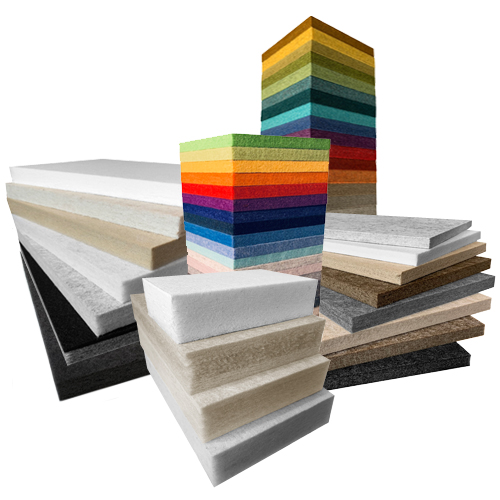

PolySorb Polyester Acoustic Panels are more efficient and cost effective than most other sound absorbing materials, providing new construction and retro-fitting environments of all budgets with another audio control option to consider. Our PolySorb panels offer outstanding sound absorption on ceilings and walls in many colors, thicknesses and installation options.

Polyester audio absorption panels have a wide variety of end uses in the field such as corporate environments, warehouses, education institutions, healthcare facilities, hospitality and convention centers, restaurants and public places, retail spaces, houses of worship and even our homes. Delivering a high degree of cleanliness, safety and consumer satisfaction.

ACOUSTICAL INSULATION – Excellent acoustical performance in sound absorption and dampening.

IMPACT RESILIENT – Very durable and able to absorb shock.

FIRE RATED – Complies with Class A fire code rating per ASTM E84.

PUT A PIN IN IT! – Pinnable tough yet soft surface with excellent holding characteristics.

TOUGH AND DURABLE – Will not rot, change color or deteriorate and is non-hygroscopic.

EARTH FRIENDLY – 100% recyclable, VOC free including formaldehyde, non-allergenic and non-toxic. Read Here

EASY TO CLEAN – Click here for cleaning information.

Easy to cut into custom shapes and light enough to suspend in many different configurations!

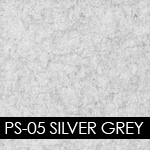

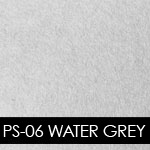

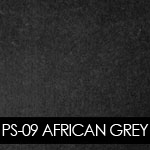

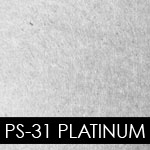

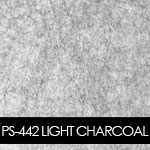

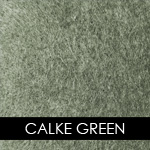

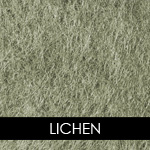

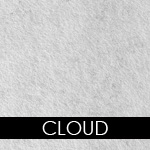

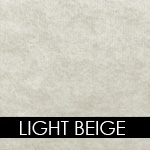

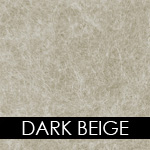

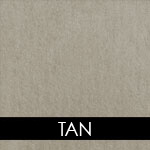

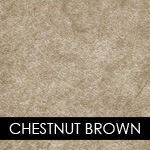

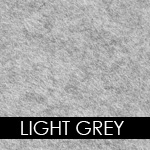

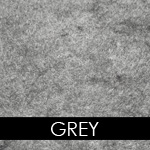

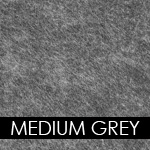

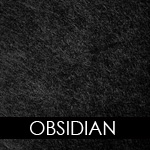

Photo colors are as close to the actual product colors as possible. We suggest you order product samples before ordering a full shipment to assure you are getting what you expect.

Polyester Acoustic Panels Call 206-571-5710

Photo colors are as close to the actual product colors as possible. We suggest you order product samples before ordering a full shipment to assure you are getting what you expect.

Polyester Acoustic Panels Call 206-571-5710

Polyester Acoustic Panels Call 206-571-5710

One of the hottest trends in commercial and industrial interior design is the rise of PET polyester acoustic panels. The use of PET acoustic panels has grown significantly in new construction, retrofits, of commercial and public spaces.

Over the past few years, PET polyester acoustic panels have seen a massive increase in demand and requirement. Due, primarily, to their spectrum of colors, durability, and ease of use when compared to traditional fabric wrapped fiberglass acoustic panels.

The industry is quick to adopt these panels as desk dividers, light fixtures, hanging sound baffles and clouds, wall-mounted art, or any number of other uses.

What quality attributes should you look for when assessing PET polyester acoustic panels?

There are several factors to consider when determining whether a PET polyester acoustic panel is of top quality.

Uniformity

The first panel should be just like all of the others panels. Also important, is each individual PET polyester acoustic panel consistent within itself?

A key marker of a poor manufacturing process is one panel not looking like the others. When dealing with large-scale install projects, even a small inconsistency problem will stand out when looking from panel to panel and section to section. Unfortunately, due to the nature of the panel manufacturing process, it is impossible for panels to be exactly identical even in the best of manufacturing facilities, but PolySorb strives for the best panel consistency available.

Blending

Equal distribution of colors in a PET acoustic panel is one of the first things that will be evident. Many of our colors have a “marbled” look to them. This happens when blending two or more colors of fiber together. This is common and less evident the further the panel is away from the eye.

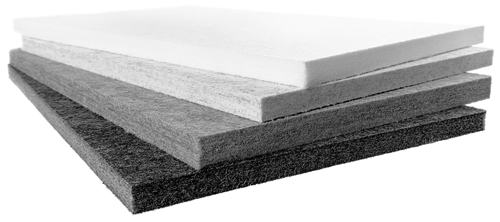

Thickness

Another one of the most important considerations is comparing the thickness of panel to panel. When placing panels next to one another on a wall or in a line, check to see if the panels are a consistent thickness.

The thickness of a PET acoustic panel is one of the major drivers of its acoustical absorption capability. Thicker is better, and consistency will be obvious!

Stiffness

Many applications for PET acoustic panels, require very rigid panels. Check if the panel is stiff enough for your specified use. Is each panel consistent? This could be from corner to corner and from end to end.

Many manufacturers have a hard time getting adequate heat through the panels to fully activate the low melt fibers. This is especially evident on thicker panels. Often, an inferior panel will have a softer center and hard surface faces when you look at the panel from the edge. If this happens, the panels do not hold mounting PETClips or suspension hardware very well and can collapse and bend easily. This usually destroys the PET acoustic panel by creating unwanted wrinkles on the surface.